Details

.jpg)

五一.png)

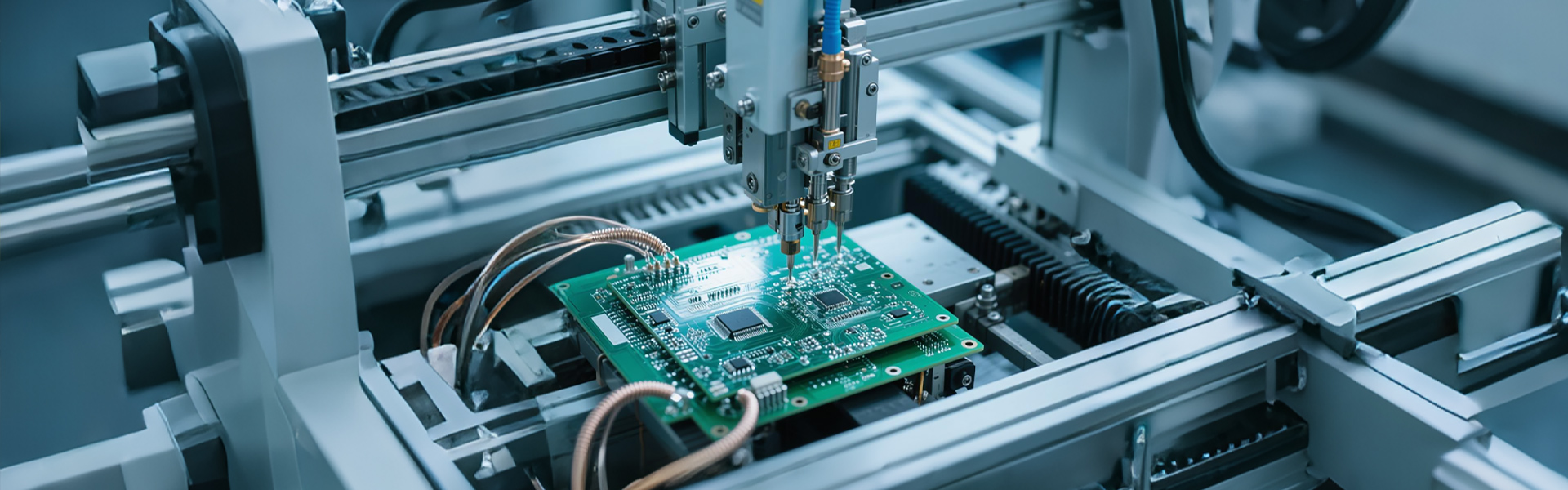

1. A simple programming method that can directly input the coordinates of the solder joint, teach and reproduce the position of the solder joint coordinates, and simply operate the Chinese teaching box to guide the end of the movement to reach the solder joint position.

2. Multi axis linkage manipulator, all driven by precision stepper motors and advanced motion control algorithms, effectively improves the positioning accuracy and repeatability of the moving end (soldering iron tip).

3. Flexible and diverse soldering methods, supporting both electric welding and drag welding. All process parameters can be set by users to adapt to various difficult operations and micro soldering processes.

4. Single and double Y-axis options, single and double soldering heads are available for higher production efficiency and faster speed. The product is placed in the front process and picked up in the back process, truly achieving unmanned operation.

5. By using imported WELLER temperature control, welding can be carried out at lower temperatures, ensuring that your products are not damaged due to high temperatures.

6. A stable WELLER system can keep the temperature set by the soldering iron tip stable, without waiting for the soldering iron tip to warm up due to heat being absorbed by parts or PC boards, and only during automated operations

This phenomenon will not cause poor welding quality.

7. Rapid heating and cooling, it only takes 7 seconds for the room temperature to reach the set temperature of 300 ℃, and it can be warmed up within 0.1 seconds (within a temperature difference of 10 degrees), with a temperature error of ± 1 ℃

Dynamic soldering machine - parameters

| model | DH-500 | |

| Overall dimensions | L815×W600×H880(mm) | |

| work schedule | X-axis | 400mm |

| Y-axis | 400mm | |

| Z-axis | 100mm | |

| R-axis | ±360° | |

| Axial speed | 0-500mm/s | |

| Motion accuracy | XYZ axis | ±0.01mm |

| R-axis | ±0.02° | |

| temperature control | 80℃-600℃ | |

| Temperature control accuracy | ± 2 ℃ (no air flow, no load) | |

| Tin delivery speed | 0-50mm/s | |

| Applicable tin wire diameter | 0.5/0.6/0.8/1.0/1.2mm | |

| Workbench load | 10㎏ | |

| Program storage | 999 of them | |

| control system | PLC PID | |

| Number of welding heads | 1 piece | |

| thermostat | Single output | |

| Tin delivery mechanism | Single tin delivery mechanism | |

| ambient temperature | 0-40℃ | |

| relative humidity | 20%-90% | |

| atmospheric pressure | 0.4Mpa | |

| power supply | 220V 50Hz | |

| weight |

About 70kg |

|